what is RFID?

Why RFID in tires?

RFID technology is a market standard technology used for identification. RFID means Radio Frequency Identification: it is a passive electronic chipset that can exchange data with a reader using Radio Frequency (RF) signals.

RFID tags embedded in tires ensure reliable tire identification and enable to build data driven services & solutions: it is a key pillar of connected mobility!

What is it made of?

RFID in tires is composed of 3 main components :

Hardware

A chipset and an additional antenna “protected” by two rubber pieces cured into the tire.

Identifier

A Unique Item Identifier following GS1 EPC Global Coding Scheme for Item Identification with 96 bits (SGTIN96) that is permalocked to ensure authenticity. It contains in particular a company prefix, an item reference and a serial number.

Cloud Service

Data associated to each tire ID (SGTIN96) are accessed by a standard cloud service

RFID: A MARKET STANDARD FOR TIRES

At ISO level, the tire industry came to an agreement on the RFID communication protocol, the tire serial number format (SGTIN96), the definition of tire tags and their attachment to tires, and conformance test methods. 4 ISO standards were published in 2019 and 2020: ISO 20909, 20910, 20911, 20912.

Actually when it comes to RFID, it refers to several technology and frequency ranges. RAIN technology is the one adopted by the tire industry referring to a passive (battery-free), UHF (Ultra High Frequency) RFID wireless technology which operates from 860MHz to 930MHz according to ISO/IEC 18000-063.

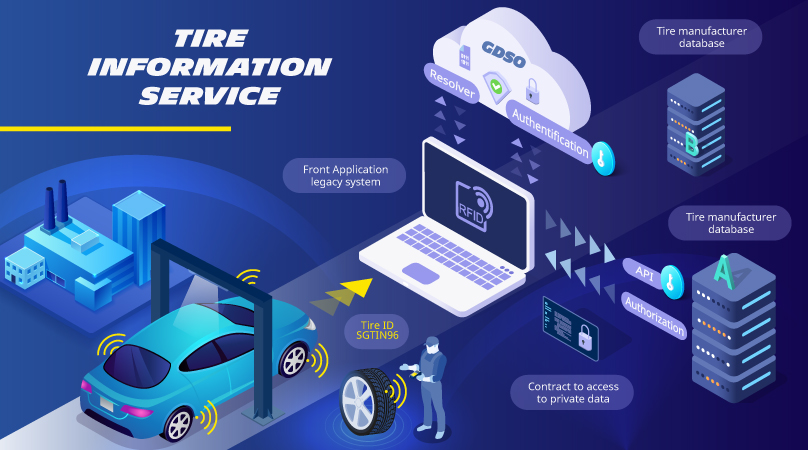

To ease access to tire data between several tire manufacturers, GDSO (Global Data Service Organization for Tires and Automotive Components) is one the first industrial Dataspaces at scale-up stage. The purpose of this new organization is to provide connectors like Tire Information Service, enabling to retrieve data associated to each tire ID (SGTIN96) in the relevant tire manufacturer's databases. A data referential lists all standardized data that can be communicated through public or private access thanks to a standard API.

The implementation of RAIN RFID embedded tags into tires and GDSO are key levers in the digitization of the tire industry, allowing the development of new services connecting tires from different companies.

Why is RFID the most adapted solution?

This technology, present in Michelin tires, is a market standard which is unique, unfalsifiable, permanently readable (even when moving) and in all conditions (until end of life)!

Universal technology

- Billions of new things are daily connected with RAIN RFID

- More than 100 millions of tires are already equipped with RAIN RFID tags

Permanently readable

- RFID used in tires is a passive technology that doesn’t require a battery

- Tire tag can be read even when the tire is moving or rolling

Remains in good conditions during entire lifecycle

- Tire tag is robust against any tire solicitations, ageing, weather conditions

- Tire tag is embedded into tire and can’t be removed, it's not an accessory

Secure

- Tag is locked after writing by the tire manufacturer

- Robust traceability technology against robbery and counterfeiting

Standard

- 4 ISO standards describe RFID use for the tire industry

- Access to tire data from different tire manufacturers will be eased by GDSO and a tire information service

Technology Licensing

Want to adopt RFID technology?

Michelin owns patents on Tire RFID in different domains (Tire tag, tag / tire components, process, tire implementation) and opens some of its patents for licensing to foster deployment of RFID in all tires in the market. If you are a RFID tire tag makers, RFID tag component makers and/or tire manufacturers, you can get in contact with us to open discussions around Intellectual Property Licensing.